A picture that calms down the Chinese elite!

- Categories:Company news

- Author:

- Origin:

- Time of issue:2018-04-23

- Views:

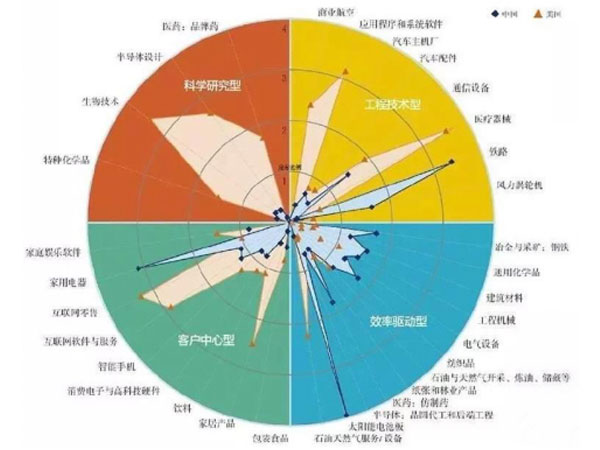

(Summary description)This radar map of the technological gap between China and the United States released by McKinsey is worth collecting.

A picture that calms down the Chinese elite!

(Summary description)This radar map of the technological gap between China and the United States released by McKinsey is worth collecting.

- Categories:Company news

- Author:

- Origin:

- Time of issue:2018-04-23

- Views:

After ZTE has just extinguished and attacked Huawei, Trump’s trump card is this picture! The big danger is the big opportunity!

This radar map of the technological gap between China and the United States released by McKinsey is worth collecting.

This is a picture that can calm the Chinese elite! The trade war is a comprehensive multi-round game based on strength. Only by knowing the enemy can the chance of winning be increased.

This precise blow to ZTE has a strong deterrent effect, and now it is administratively summoned to Huawei. Trump has gained a lot of negotiating weight in this round!

Although we have already seen that Trump’s trump card is absolutely impossible for a full-scale trade war, one is because businessmen will not do a lose-lose thing, and the other is that the U.S. system makes him unable to bear the consequences of a real fight: the domestic result is inevitable. It was him who stepped down. In this regard, China's system is much more capable of resisting shocks and withstanding difficulties. The big danger is the big opportunity!

The country can take the pains of the trade war, concentrate N times the number of people and property, introduce more powerful policies, vigorously develop high-tech industries and chips and other high-tech technologies, deepen internal reforms and multiply the scale and quality of the private economy, which will waste real estate and Huge funds in low-energy, low-efficiency and surplus areas such as mixed reforms have been directed to these key areas that determine China's future competitiveness! We have to "thank" Trump for intensifying foreign aggression and accelerating the consensus on deepening China's internal reforms!

Trade wars mainly take place in these fully competitive fields, and private enterprises are the main force in fully competitive industries! This round of China's deepening reforms catalyzed by the trade war will once again release and stimulate the scientific and technological vitality of the private economy, and China will undergo major changes. The strong historical process will be realized at double speed.

01. Now the trade war is being loaded with bullets. Only when the trigger is pulled, everyone is murmuring. What is Trump doing?

Solve the trade deficit, boost employment, and build momentum for the mid-term elections? Adhere to China's non-market economy and maintain the operation of the international trading system?

This is no longer a simple trade imbalance issue. It seems that it has evolved into an industrial competition between the two big powers, which is a comprehensive containment of the rising power of the emerging big power by the preserving power.

02. The U.S. media is highly vigilant about China's technological rise, and China's WeChat self-media has the accusation that "the U.S. is scared to pee".

As early as February this year, Stratfor, a well-known geopolitical think tank in the United States, released "The Coming Tech War against China". The report praised China’s remarkable achievements in the fields of hypersonic missiles, human gene editing technology and quantum satellites in recent years. A faint sense of pride swelled in the chest. It also constantly questioned whether American technology companies could catch up with their Chinese counterparts. Breakthroughs in the field of artificial intelligence:

Artificial intelligence will bring a complete revolution to the military and people's livelihood, and China is pressing the United States step by step in this regard. The three-year artificial intelligence plan issued by the Ministry of Industry and Information Technology at the end of 2017 revealed China's ambition to achieve self-sufficiency in the core technology field. The Chinese government even formed a "dream team" with private technology giants.

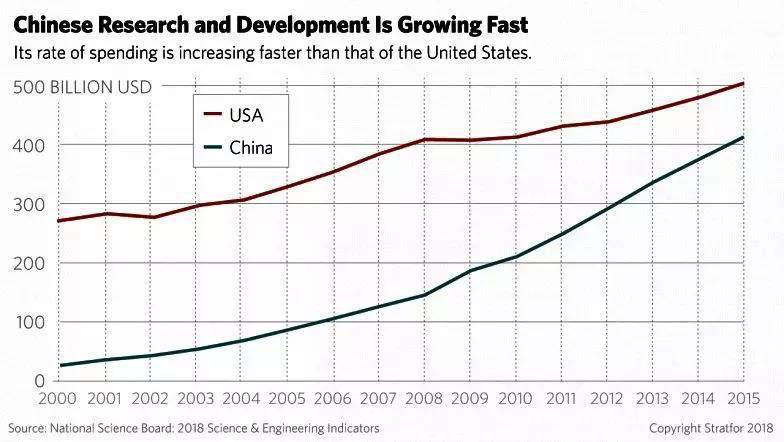

(Comparison of R&D expenditure between China and the United States, please note that the unit is 1 billion U.S. dollars)

In the week before China and the United States were tit-for-tat, the British "The Economist" used the cover report "Sino-US Technological Hegemony" to join in the excitement, saying that "the witty I have already seen everything":

"Designed in California, Made in China", the words behind Apple's mobile phone once represented the division of labor between the world's two largest economies. Now that the battle is changing, the technological threat China poses to the United States has caused the United States to panic. Will the Sino-U.S. technological hegemony trigger a trade war?

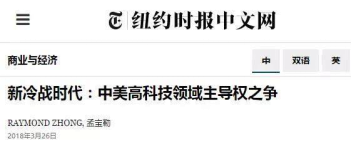

The New York Times used more harsh words. The Sino-U.S. trade war will accelerate the world’s most advanced industries into the new Cold War era, which is colder than the U.S.-Soviet Cold War, and more difficult to solve than the U.S.-Japan trade war:

In the past, Japan was a competitor in technology, but an ally in the military. The Soviet Union is an adversary in defense technology, but it is far inferior in business... But China has strong scientific and technological strength and funds when competing for cutting-edge fields such as artificial intelligence, quantum computing, and the next generation of wireless Internet.

Obviously, Western media don't think this is a trade war between soybeans and sorghum, one steel and one aluminum. The United States is very afraid of China's achievements in top-notch technology in recent years, and it is enough to launch a battle for technological hegemony for this.

Is it really so powerful for my country? In the past few years, China has been so strong that it has overwhelmed the United States in high-tech fields?

High-energy warning, below you will see that Americans have a serious lack of awareness of their own national conditions!

03. How did the United States reach its peak in the field of top science and technology, and how outrageous it is.

(1) The U.S. can constrain China's manufacturing with a single engine

Why is China's first domestically produced large aircraft C919 only equivalent to the Boeing 737 of the United States 50 years ago?

Why is China’s current helicopter with the best plateau performance being the American "Black Hawk" purchased from the United States in the 1980s?

Why is there a gap of about 10 between the Chinese fighter jet fighter J-20 and the U.S. F-22?

The most important thing is the "heart" problem. Marking a country's most sophisticated, powerful, and most intensive field of science and technology, it is undoubtedly the aviation industry known as the "modern industrial crown", and the jewel in the crown is the aviation engine. However, China has exhausted its efforts for more than half a century and has yet to create a mature and reliable core machine.

The top technologies currently mastered by the United States are: mature civil turbofan engines with large bypass ratio, fourth-generation military low-bypass ratio high-thrust turbofan engines, fifth-generation military non-geometric structure conversion variable-circulation turbofan engines, military/civilian High-power turboshaft/turboprop engine......

Because of the two F119 engines with afterburning thrust of 156 kN, the American fighter F-22 can make many incredible maneuvers. It is also the only fighter in the world that can cruise at supersonic speed without afterburner. It is the hegemony of the U.S. military. Vital.

Because of the four TF39 turbofan engines with a thrust of 191 kN each, the US C-5 Galaxy dare to say loudly that it is the world's strongest transport aircraft, none of which is currently in service. The upper cabin can carry 75 passengers. Under full load, it can take off within a distance of 2,300 meters and land within a distance of 1,493 meters. The load capacity of the fuselage can be estimated as: 100 Volkswagen Beetles/6 Greyhound buses/6 Apache helicopters/2 M1A2 main battle tanks/1 C-130. Development began in 1961 and entered service in 1970.

Aeroengines need to work under severe conditions of high temperature, high pressure, high speed and high load, and meet the requirements of large thrust/power, light weight, high reliability, good safety, long life, low fuel consumption, low noise, low pollution, etc. Very demanding and conflicting requirements.

Therefore, it also involves countless disciplines such as materials science, aerodynamics, thermodynamics, and structural mechanics. It is one of the most complex and multi-disciplinary integrated engineering machinery systems in the world today. The shortcomings of any discipline will lead to the limitation of the level of aeroengines. It is no exaggeration to say that the level of aeroengine is the level of a country's basic science and manufacturing industry, of course, plus the ability to burn money.

This is why, as a "counterfeit country", after so many years of research, it has yet to come up with a mass-produced engine that represents China's high-end manufacturing. It is impossible to make a breakthrough in this high-precision field. Naturally, he can understand why Han Han, who has been a racing driver, complains that China cannot provide a decent car engine.

(2) U.S. unique giant astronomical telescope dominates the optical field

The high-quality digital cameras Nikon and Canon in daily life are all from Japan, but in fact, when the United States launched the Hubble Telescope (carrying a 2.4-meter-diameter giant lens), Japan could not process the same type of equipment at the 0.5-meter level.

The United States is the world's high-end optical power, and only the United States can process super-large-diameter optical lenses.

Let you see what is the real "journey is the sea of stars": Recently, NASA said that the Webb telescope, called "the most powerful telescope in history," originally scheduled to enter service this year, will be postponed to 2020 in order to allow engineers to have more More time to ensure the success of the task.

This giant telescope has an aperture three times that of the Hubble Space Telescope, and is about 100 times more sensitive than Hubble, yet its mass is only half that of Hubble. Its main task is to investigate residual infrared evidence as the Big Bang theory. After deployment, it will allow astronomers an unprecedented glimpse of the first galaxies formed at the beginning of the universe.

While the United States is developing a 100-meter-diameter super thin-film lens equipment, China is still working on a 4-meter-diameter large-scale giant lens equipment, and the technological gap is naked.

Even worse, the giant lens equipment system is the core key equipment of military optical reconnaissance satellites and reconnaissance systems.

Today’s best optical imaging reconnaissance satellite is the American Keyhole-12 (KH-12), with a ground resolution of 0.1-0.3 meters, which can count tanks, tents, and personnel in the desert.

The U.S. civilian remote sensing satellites are not bad either, shooting 0.35-meter satellite photos of Pudong New Area in Shanghai

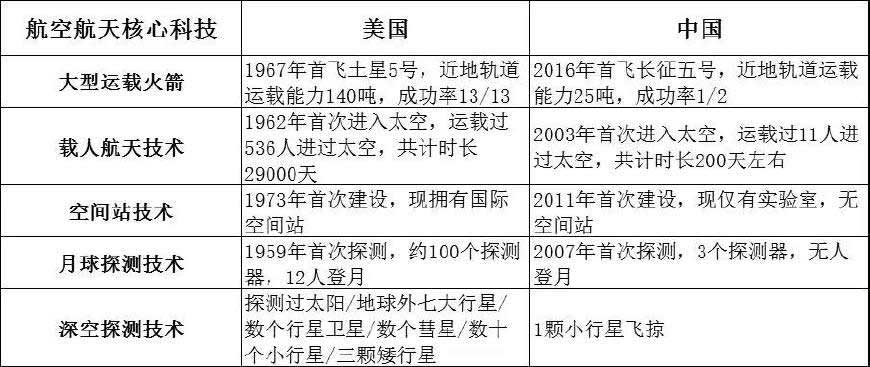

The two high-end technologies of engines and optics largely determine how far a country's aerospace technology can go. China has indeed made many breakthroughs in the past ten years, but the gap with the United States is still huge.

In addition, the United States has made no breakthroughs in the design and manufacture of heavy/super-heavy rockets, space station technology, lunar exploration technology, and deep space exploration technology.

(3) New materials that disrupt the industry

Using the right new materials in key components is likely to achieve a subversion of the entire industry. In addition to the new heat-resistant materials on the engine fan, how good is the use of new materials in the United States?

Let me talk about the "confidential" level first.

The American B-2 ghost, which is full of science fiction and once made the world tremble, is the only stealth strategic bomber in the world, each costing 2.4 billion U.S. dollars. Most of the surface of B-2 is covered by a layer of special elastic material to maintain uniform conductivity on the surface to reduce the reflection of radar waves from joints or joints. In the design, the parts that cannot rely on the shape for stealth (such as the air intake) must be coated with radar absorbing material (RAM), and its composition is still highly classified. It was developed in the mid-1970s and entered service in 1997.

Another masterpiece of alien appearance, the reconnaissance aircraft SR-71, the Blackbird, which has not been shot down by any enemy aircraft or anti-control missiles in the actual combat record, is still the fastest manned aircraft in the world. Blackbird’s technological breakthrough lies in the thermal barrier. Above three times the speed of sound is the thermal barrier area. The maximum speed of the Blackbird is Mach 3.35. At this speed, aviation aluminum will become brittle and soft, so the blackbird uses low weight and high strength. Titanium alloys and composite materials are the real technological key.

Let's take a look at the more "grounded":

A. Lithium-air batteries are expected to disrupt the electric vehicle industry

The US Tesla Model S has a maximum cruising range of 540 kilometers and uses a "ternary lithium" battery, which is the longest range of all electric vehicles.

But recently another news came from the United States that they have created lithium-air batteries, which greatly inspires the field of electrochemical energy storage.

This battery with extremely high theoretical energy density has been successfully charged and discharged 700 times, breaking the previous limitation that lithium-air batteries can only use pure oxygen and have a short cycle life. It is expected to replace the most successful rechargeable battery lithium-ion battery so far. The bottleneck of electric vehicle mileage.

B. Semiconductor overlord who cannot be easily challenged

"Semiconductor King" Intel announced that it will launch several 3D XPoint memories this year, with a maximum capacity of 512G. The industry exclaimed that this is a revolution in the PC field.

Tsinghua Unigroup expects to launch DDR4 memory modules this year, with a maximum capacity of 128GB. At present, it is still stuck in the third-generation technology DDR3, with a single maximum capacity of 64GB.

Semiconductor materials are widely distributed from mobile phone chips to cruise missile controllers, from civilian to military, and are the core technology of the electronic information industry. US semiconductor production has accounted for 48% of the global market for many years, and Intel’s research and development expenditure alone has reached four times that of the entire Chinese chip industry.

According to the statistics of the American Semiconductor Industry Association (SIA), the annual semiconductor sales of the entire Chinese market is about 100 billion U.S. dollars (China's self-sufficiency rate is less than 10%), of which the market share of American companies is close to 60%, and the amount of US companies exported to China is at least Above 50 billion U.S. dollars.

However, the United States has never relaxed its "blockade war" against China in the semiconductor field.

During the Cold War, Europe, America, Japan and other countries organized a Paris Coordinating Committee (Batumi for short) to restrict foreign technology exports. After the Cold War, Batumi was dissolved. However, the United States immediately established the Wassenaar Agreement with many countries to continue to restrict the export of foreign technology, especially high-tech technology, and semiconductor technology is the focus of it. Therefore, according to US export regulations, 14nm chip manufacturing can be moved to China, but Intel’s X86 CPU design and other key technology designs must not leave the United States.

In recent years, China has invested tens of billions of dollars in the semiconductor industry, China’s Made in China 2025 requires self-sufficiency in chip manufacturing, and Tsinghua Unigroup and HiSilicon are among the top ten global semiconductor companies. The United States has become more strict with Chinese semiconductors. .

In this Sino-US trade war negotiation, Trump's request is very clear, hoping that China will continue to increase imports of US semiconductor chips.

At the same time, in recent years, the U.S. authorities have used "national security" as an excuse for several acquisitions initiated by Chinese companies to acquire U.S. semiconductor companies:

In December 2015, Tsinghua Unigroup acquired US chip storage giant Micron for US$23 billion;

In February 2016, Huachuang Investment and China Resources led the acquisition of Fairchild Semiconductor in the United States for US$2.6 billion;

In September 2017, Canyon bridge, a private equity firm with a Chinese background, acquired Lattice, a US chip company, for US$1.3 billion;

...

In February 2018, Hubei Xinyan, a Chinese semiconductor investment fund, purchased US semiconductor test equipment manufacturer Xcerra for US$580 million;

In March 2018, a Singapore Broadcom acquisition of Qualcomm was rejected because Qualcomm was one of the few wireless chip companies that made long-term investments, and the other was Huawei. Trump is worried that after Qualcomm is acquired, Huawei will replace it as the leader of 5G wireless standards.

(4) Profitable but beneficial biopharmaceuticals

The absolute leader in the field of American biopharmaceuticals, the number of biopharmaceutical companies ranks first in the world, and Wall Street capital is also crazy about biopharmaceuticals. In 2017, there were 11 American companies in the TOP25 global IPOs of biopharmaceutical companies.

Such as tumor drugs. According to Professor Yu Dechao of the Chinese Academy of Sciences, the United States has approved 48 new drugs in the past few years. Basically, there are 1-5 new drugs on the market for every tumor. For example, five years ago, doctors had only three medicines for lung cancer. Today, doctors can choose more than a dozen medicines for lung cancer. The incidence and mortality of tumors in the United States have plummeted. Today, the five-year survival rate for cancer in the United States is 70%, while China is less than 30%.

Such as vaccines. The United States is currently basically a polysaccharide vaccine with no live bacteria and strict requirements. Phenolic fungicides cannot be used. It has even begun to market protein-binding vaccines with stronger targeting and immunity.

The main force of domestic vaccines in China is still live bacteria, attenuated vaccines such as BCG vaccines in the early 20th century. How much toxicity is reduced is the real safety, and there is no absolute indicator at all.

China's high-end drugs are basically imported from European and American countries. Speaking of this, I have to mention medical equipment and medical consumables. The market is almost dominated by foreign brands. Among them, General Electric has properly established the market in nuclear medicine, ultrasound imaging, magnetic resonance MRI, and CT.

(5) Artificial intelligence

This top technology that was considered by Robert Walker, the former Deputy Secretary of Defense of the United States, will change the nature of future wars and the form of conflict, and the United States also maintains its leading edge.

The familiar human-computer interaction function Siri on Apple mobile phones is a CALO project invested by DARPA in 2003 by the Advanced Research Projects Agency of the US Department of Defense, and this project can also be traced back to Stanford University’s artificial intelligence research in the 1960s.

Alpha Go developed by Google is the first artificial intelligence program to defeat human professional Go players and the first world champion of Go.

In the past year, Google’s Waymo has reached 350,000 miles of autonomous driving in California, and the number of times it has left the autonomous driving mode and taken over by the driver is only 63 times.

In addition to what the United States owns, through capital and laws, there are more top technologies that the United States can control beyond imagination.

For example, the Chinese Wuzhi 10 engine used a Canadian civilian model during the test flight. This model was better than China's best military products at the time, but the United States said no, and Canada did not dare to sell it again. As a result, China Wuzhi 10 had to be redesigned at the last minute.

Such as civilian computer systems, databases. China's large state-owned state-owned enterprises still have to purchase systems from Microsoft and purchase data management services from Oracle.

This radar map of the technological gap between China and the United States released by McKinsey in 2013 is still outdated. It will take at least 20 years for China to catch up with the current technological achievements of the United States.

When the economic gap is getting smaller and smaller, China should pay more attention to whether the technological gap can keep narrowing at a corresponding speed.

Although the West has been focusing on the scientific and research progress that China has made in recent years:

China was the first to develop a high-performance quantum radar in the world, China was the first to design a quantum computer, China was the first to develop a quantum communication satellite, and China was the first to complete an anti-communication quantum experiment. The first breakthrough in all-electric propulsion technology was China, the first breakthrough in four-wing tiltrotor technology was China, the first independent space station was built in China, and the first to achieve continuous mining of combustible ice was China...

China does have confidence in Made in China 2025, but we must also see the real gap. Behind the technological gap between China and the United States is not only the competition between major powers in scientific and technological research and development, but also the hard work of several generations of research, persistence in innovation, and respect and protection of intellectual property rights.

04. The cruel reality of China's manufacturing industry: a small foreign company can paralyze China's trillion-level industry

This is a good article with an in-depth analysis of the domestic manufacturing industry. It explains the core issues and some key issues in the process of China’s industrialization, involving technology, talents, systems, policies, and many other fields. It also points to the weaknesses and weaknesses of China’s industrialization. The pain point, in this impetuous society, it is not easy to solve these problems. The author also proposes solutions and methods.

The "hidden champion" of the industry refers to a little-known small and medium-sized enterprise that is absolutely leading in a certain market segment and has become the world's top three in its own field. Most of the "invisible champions" are located in the upper reaches of the industrial chain, because they do not have direct contact with end consumers, and their public awareness is relatively low, hence the name "invisible".

However, because of mastering the industry's core technology, key components or key materials, it enjoys an irreplaceable position and is the real behind-the-scenes controller of the industry. It is said that there are more than 3,000 hidden champion companies in the world, and Germany has 1,307, the largest number. Although China is the world’s largest manufacturing country and the world’s second largest economy, many industries are also among the world’s largest in scale, but these industries are often large. It is not strong. The fundamental reason lies in its core technology. Most of the key components and materials are monopolized in the hands of foreign "hidden champion" companies. Please add WeChat public account: industrial intelligence (robotinfo) Jack Ma is paying attention

Therefore, if China's industry is to grow stronger and have the right to speak, more "hidden champion" companies are needed to focus on solving the industry's key technologies, core components and special materials, and provide professional and high-quality products and services.

As we all know, although my country's integrated circuit industry has developed by leaps and bounds in recent years, the problem of "core shortage" with a high degree of external dependence has always been the biggest pain point: core technology is controlled by others, and key components and materials have long been monopolized by foreign companies. 90% of domestic chips rely on imports, which exceeded US$220 billion in 2016. Many industries in China are like the electronics industry. Because of the lack of "core", they are large but have no right to speak. For example:

China's steel production is the largest in the world, but a large amount of special steel needs to rely on imports;

China's high-speed rail is China's business card, but the core power system and control system must come from foreign companies such as Siemens and ABB, and even the screws are dependent on imports;

China's production of ballpoint pens is the largest in the world, but it cannot produce ballpoint pen cores;

China's PC production is the first, but computer chips are basically monopolized by Intel and AMD in the United States;

The Chinese auto market ranks among the best in the world, but the engine has always been constrained by others.

Looking at the development of China’s industry, although the scale is large, due to the lack of a “core” such a fatal shortcoming, the industry is always at a disadvantage of “passive beating”, while developed countries control core technologies and key materials or key components. Firmly control the industry initiative.

I saw a news some time ago that BOE burned hundreds of billions of yuan and became the world's largest manufacturer of flat panel displays. The shipment volume of smartphone LCD displays and tablet computer displays ranks first in the world, and LCD TV displays. Third in the world, it has changed the situation that China imports hundreds of billions of yuan worth of LCD screens every year.

To be honest, I am very impressed after seeing this news. On the one hand, it can be seen that China has indeed undergone earth-shaking changes since the reform and opening up. Many industries have gone from blank to the largest in the world just like the flat panel industry, solving a large number of employment problems and increasing China's GDP. The country has also developed from "one poor and two white" to the world's second largest economy;

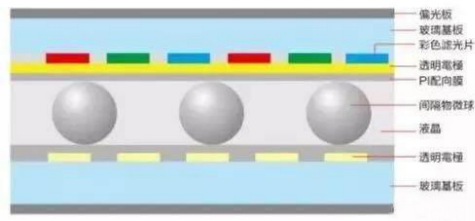

On the other hand, it has aroused long-term worries and worries about China's industrial development being large but not strong, focusing on output value while neglecting research and development, focusing on scale and ignoring core technologies! At present, many core technologies, key materials and components of China’s industries have been Companies in developed countries such as Europe, America and Japan are monopolized. Most of these monopolies are hidden champions of the industry. They are the only or very few companies in the world that can achieve the ultimate in essential and irreplaceable key components and materials for modern high-end industries. As large as precision machine tools, semiconductor processing equipment, aircraft engines, as small as ball-point pen cores, high-speed rail screws, chips in the electronics industry, spacer microspheres for liquid crystal displays, conductive gold balls for microelectronic links, and analysis and testing Chromatographic column packing, separation and purification chromatographic media for biopharmaceuticals, etc.

It can be said that if a small invisible champion foreign company does not supply relevant materials, it can paralyze China's trillion-level industry. This is not alarmist, but the cruel reality we face.

Therefore, as long as the irreplaceable key components and materials are in the hands of invisible champions abroad, no matter how large China's industry is, it will not be able to get rid of the passive situation of "assembly factories and low-end operation". At present, China should dominate any strategic industry, promote the national economy to move toward the high-end of the global value chain, realize industrial transformation and upgrading, and enhance economic innovation and competitiveness. It is not relying on the downstream giant assembly and processing plants that invest more. Instead, it is necessary to cultivate more upstream invisible champion companies with independent core technologies, key materials and components, so as to have core competitiveness in major industries, in order to break through the bottleneck of China's economic development.

The invisible champion will become the decisive point and key for China to move from a manufacturing power to a manufacturing power.

Analysis on the Resource Advantages of China's Rapid Industrial Expansion

In recent years, China has gradually become the world's manufacturing center, and the scale of many manufacturing fields has leapt to the first place in the world. This is due to the four unique resource advantages of China:

One is market advantage. China is a large country with the largest population in the world, with huge purchasing power, and with economic development and wealth accumulation, the market potential is increasing. The huge consumer demand has enabled Chinese companies to develop rapidly, and it is very easy to form large-scale industries. At present, many markets in China have become the world's first in demand, such as steel, plastics, food, electronic devices, etc.;

The second is labor advantage. China has a large population and can provide abundant labor resources for industrial development. Therefore, labor-intensive light industries such as clothing, textiles, toys, leather, etc. and downstream assembly industries such as flat panel displays have absolute development advantages in China;

The third is capital advantage. Since China's reform and opening up, the country has accumulated a large amount of wealth and capital, which can provide strong financial support for industrial development;

The fourth is the advantage of the system. China is a centralized country. Under the conditions of a socialist market economy with Chinese characteristics, the country can concentrate all kinds of resources and forces to do major tasks. In order to enhance the competitive advantage of strategic industries, relevant preferential policies can be introduced at the national level, and even huge investment in support regardless of cost.

Whether it’s the BOE LCD panel we mentioned earlier

The industry, or the high-speed rail that we are proud of, is a good case. With the support of the state, China’s backward LCD flat panel display production technology can be quickly changed, and the annual import of hundreds of billions of LCD screens can be ended. The state strongly supports BOE’s investment. Hundreds of billions of renminbi to build the LCD panel line, even if the company's huge losses for many years can continue, and finally become the world's largest company in LCD panel shipments. Without strong national policies and financial support, and relying entirely on market-oriented operations, BOE will probably not be able to survive, let alone sustainable development.

Similarly, the rapid expansion of China's high-speed rail to become the number one in the world is also due to the strong support of national finance and government resources.

Research on the part-time job mode behind scale

Quite a few industries in China are expanding rapidly in a short period of time, and under the strong background that there is no shortage of market, no shortage of people, no shortage of money, and no shortage of government support, why is there always excess scale and insufficient competitiveness? The main reason is China. The economic development process is short, the technology accumulation is small, and the research and development capabilities are weak. Many core technologies and key materials are monopolized by developed countries.

The ZTE chip incident and the Huawei memory incident clearly exposed the embarrassment and helplessness of the Chinese industry's fragility, vulnerability, and lack of voice. Take the LCD industry as an example. Although China's LCD panel industry is large in scale, it is basically a processing and assembly type. Not only the production line must be imported from Japan, but also many key materials for manufacturing panels must be imported.

Therefore, the seemingly prosperous production is actually made by Japanese equipment and material manufacturers. The Japanese moved LCD panels to China only to use China’s abundant labor, land resources and a large amount of capital. They can easily obtain huge profits from China by relying on the monopoly of key materials and equipment, and then use these profits for development. The new display technology will be upgraded and then sold to China to make more profits. As a result, Chinese companies in the downstream of the industrial chain have been buying, buying, buying, buying from the 5th generation line to the 6th generation line, then to the 7th generation line and 8th generation line, to the current 10th generation line, each line investment has reached tens of billions. .

What’s even more astounding is that these amazingly-invested production lines require key Japanese technology and materials to produce. That is to say, the start of the production line means that China must purchase a large amount of Japanese materials at the same time, and the supply will be cut off every day. Yiyi Investment's production line was immediately paralyzed.

An invisible champion company in Japan that masters key materials can get stuck in the neck of China's trillion-dollar industry. In other words, if the Chinese do not possess the core technology, no matter how large the industry is, it can only be in a passive position at the discretion of others.

So, why doesn’t China rely on the huge scale of the display industry, numerous application talents, and the state’s capital support to develop and innovate its own display production technology and get rid of the passive situation of working for others? It’s not that we don’t want to do it. It is because the development of new display technology often requires the cooperation of upstream material manufacturers. Currently, most of the key upstream materials are monopolized by Japanese hidden champion companies. Even if scientists in China display technology have good technology and ideas, if there is no supply and cooperation from upstream material manufacturers, it is like a clever woman who can’t cook without rice.

This is the grim reality facing China!

If you want to truly take the destiny in your own hands and make Made in China a benign interaction in the entire industry chain, you do not rely on buying more, larger, and more advanced downstream assembly lines. Although relying on the purchase of assembly lines can increase employment, To rapidly expand GDP, we must be determined to start from the source, guide and support companies to focus on the R&D and manufacturing of core technologies and key materials, focus on the ultimate in core components and upstream products, and focus on becoming an invisible champion company in market segments , To break through the bottleneck of key materials and core component manufacturing to break the encirclement of foreign companies, and provide a solid foundation for the restructuring of the development path of China's industry.

Unlock the "password" that restricts key technologies

The scale of a country’s industry often depends on the market, labor, land resources, and national capital strength. Relying on the advantages of a large market, abundant labor resources and strong national capital strength, China has successfully expanded many industries in a very short period of time. However, the development of key materials and core components of modern industries has nothing to do with the market, labor, land resources, and national capital strength. Instead, it depends on a country's overall technological innovation capability, industrialization level, and comprehensive national strength. These are precisely the gap between China and developed countries.

From a strategic perspective and overall perspective, the breakthrough capability of key core technologies determines the success or failure of corporate competition and even international competition, and even has a huge impact on national security and the survival of the nation. Key technologies in many fields in my country have long been constrained by others. Only by breaking through the technical bottlenecks of key materials and core components and breaking the long-term monopoly of foreign companies can China's major industries have the right to speak in the world, and China's industries can become stronger. Judging from the actual situation, there is still a long way to go to achieve the above goals. We must clearly understand that the current breakthroughs in the research and development of key materials and core components are not only technical issues, but more external environments and national policies. , And deep-seated issues such as corporate cognition and entrepreneurial mindset.

基础原料和装备差导致研发速度受阻

High-end emerging industries such as liquid crystal displays have extremely high requirements for the performance and quality of key materials and components, so R&D and production technologies are difficult. Although my country is a major producer of basic raw materials, the production capacity of stainless steel and many chemical basic raw materials ranks first in the world, but due to the lack of high-performance stainless steel and high-quality basic chemical raw materials, related materials and equipment are produced using them as raw materials. Can not meet the production needs of high-end industries.

It can be said that the quality of basic raw materials directly affects the development and industrialization of key materials and components in the industry. I returned to China to start a business for LCD displays. The quality of the basic materials encountered by the "spacer microspheres" material that caused the delay in the industrialization process is a typical example.

The LCD screen consists of "spacer microspheres" "mixing" in the liquid crystal and "standing" between the glass panels. It mainly plays the role of "skeleton" and can precisely control the thickness of the glass panel. It is like the calcium in human bones. Without it, the LCD panel cannot "stand".

Although the liquid crystal "spacer microspheres" are only composed of ordinary polystyrene and divinylbenzene materials, the polymers used for liquid crystal displays have extremely high requirements on the quality and performance of the microspheres, and must have a high degree of particle size accuracy, Very narrow particle size distribution, excellent mechanical strength, smooth surface properties, extremely high cleanliness and extremely low metal impurities, so the preparation technology barriers are extremely high, for a long time only two Japanese companies in the world can produce.

When we developed the liquid crystal spacer microsphere material, we first encountered the problem of poor quality of domestic basic raw materials. Styrene is one of the general chemical monomers, and its domestic production capacity ranks first in the world. However, the domestic styrene and divinylbenzene have high impurity content (especially the high content of naphthalene impurity), and the spacer products produced with them have low mechanical strength and large deformation, which cannot meet the requirements of controlling the liquid crystal display. As a result, the company had to spend a lot of money. Time to solve the problem of monomer purity.

In addition, we also encountered the problem of unqualified equipment due to poor performance of stainless steel in the process of industrialization. The production of high-performance microspheres requires a stainless steel reaction kettle. After many tests, it was found that the iron content of the LCD spacer microspheres produced by the domestic reaction kettle exceeded the standard and could not meet the high-end requirements of liquid crystal display. It took a year later. , I tried a lot of domestic reactors with the same problem, but the imported iron content reached the standard. After paying such a large time cost and spending a huge amount of people and property, I got such a ridiculous conclusion; the quality of domestic stainless steel is like this, there are very few real stainless steels, and high-performance stainless steels need to be imported!

Therefore, although we have developed advanced microsphere manufacturing technology than Japan, due to the quality of domestic raw materials and the performance of stainless steel, we had to spend a lot of time and energy to solve the problem of poor basic materials before finally realizing the spacer microsphere industry. change. From this case, we can see how difficult it is for China to do research and development of high-tech products, especially key materials and key components of modern industries: not only to solve key technical barriers, but also to solve the problem of poor quality of supporting basic raw materials and equipment! I think This may be one of the important reasons why China has trained a large number of scientific researchers and published the most articles in the world, but the conversion rate of results is extremely low.

Therefore, to solve the key materials and core components of the modern industry, we must first improve the quality of China’s basic raw materials and equipment. Otherwise, even if we have many talents who can solve key materials and core component manufacturing technologies, it will be difficult to make high-performance materials and components. Components to meet the needs of modern industries.

The impetuous society and insufficient basic innovation have hindered the driving force of R&D

Since the reform and development, China has undergone rapid changes. The rapid development has also brought impetuousness and eagerness to quick success in the whole society, and has caused some extremely unreasonable phenomena. Such as rapidly rising housing prices have made real estate speculators huge wealth, while hard-working people are getting poorer and poorer. The serious irrational distribution of social wealth has led to more and more speculative mentality, which undermines China's traditional virtues of hard work and wealth, and the whole society is becoming more and more eager for quick success and quick gain, lacking the patience and perseverance to concentrate on doing one thing well.

However, the research and development and industrialization of key materials and technologies required by almost all industries require long-term investment and accumulation of experience to be successful.

However, few Chinese companies are willing to spend ten years to develop a technology and product. Everyone likes short and fast projects, and is unwilling to invest money and time in advanced technology research and development and materials with high investment, long cycle and high risk. Manufacturing field.

The hidden champion companies in Europe, America and Japan are all formed by intensively working in a field for decades to achieve the ultimate in a material or component. Therefore, if China wants to cultivate invisible champion companies, it must first have a more reasonable wealth distribution system. Social wealth should be inclined to talents who contribute to society rather than speculators, so that technical talents can settle down for a long time to achieve key technologies. The ultimate, let more companies become hidden champions.

On the other hand, although the state has invested a large amount of scientific research funds to support the development of scientific research institutes in universities, since the current evaluation system for university researchers mainly depends on the number of articles published, researchers put more energy and time on how to publish more. More articles instead of in-depth research on original technology or practical technology to solve the core technology of the industry.

The evaluation system based on the number of papers and the control and distribution system of unreasonable funds prevent researchers from sinking in to do original scientific research or focus on core technologies of industrialization, but to do research that is easy to produce articles. Make scientific research input and output disproportionate. For example, although China has already ranked first in the world in the number of articles published in the field of nanotechnology, the number of articles does not match the development of domestic industrialization technology, and the industrialization of nanotechnology and nanomaterials is basically blank. Therefore, only scientific and reasonable adjustments to the scientific research evaluation system and improvement of the incentive mechanism will enable the national scientific research investment to have more achievements transformation, better serve the industry, and better return to the society.

Social impetuousness also has a lot to do with government policies. Since the previous policy is a GDP-oriented evaluation system, governments at all levels are willing to invest in the development of downstream assembly industries that can quickly expand and easily increase GDP and employment. At the same time, due to the excessive investment of local governments, many industries have formed vicious competition after they come to China. For example, the solar panel industry is a typical example of the problem of overheating caused by excessive government investment. The upstream key materials and components require long-term R&D investment, and the scale will not be rapidly enlarged. Therefore, the government's willingness and strength to invest in this area is obviously insufficient.

It is difficult to promote in the domestic market, and the promotion of research and development results is blocked

Since most of China's emerging industries currently rely on imported foreign technologies, and key materials are all imported products. Therefore, the key materials developed by Chinese companies are faced with inherent deficiencies when they are introduced into the market.

First of all, key materials and components have a great impact on the performance of the end product. If the quality is defective, it will cause huge losses to the end customer. Therefore, under normal circumstances, customers are unwilling to take this risk, making it difficult for domestic materials to replace imported materials. .

Even if the customer is willing to import domestic brand materials, the verification cycle is very long. Although the unit price of some materials is very high, the cost ratio of the entire equipment is relatively low, and customers are even less willing to try and replace new products. For example, spacer microspheres, although the unit price is very high, due to the small amount used, they account for less than 1% of the entire display material cost. And this material has a very important impact on the quality of the entire display, so customers are often reluctant to take the risk of adopting domestic products.

Secondly, the prejudice of Chinese people towards domestic and imported products will also lead to difficulties in importing domestic products. For a long time, Chinese manufacturers have been accustomed to producing low-end products, and have not paid enough attention to technology and product quality. Therefore, the general impression is that the quality of domestic products is not good, and they are not assured of using them. Customers will be very cautious about the introduction of domestic products and even increase the import threshold. .

What's more, if a customer has a problem with a domestic product, he will blame the quality of the domestic raw material in the first place; if the customer has a problem with the imported material, he will reflect on the problem with his own process. Therefore, domestic products must be imported to customers, not only to have super-high product quality, but also to be close to customer needs, familiar with customer technology, and to help customers solve practical problems in time when they encounter problems.

To solve the problem of domestic product marketing, it is necessary to combine and reach consensus from multiple parties:

On the one hand, manufacturers of production materials must do a good The better it comes, it may even surpass imported products.

On the other hand, downstream manufacturers also need to have a more open mind and actively cooperate with upstream domestic material manufacturers. The successful industrialization of key upstream materials and components will greatly promote the international competitiveness of downstream manufacturers and achieve mutual benefit and win-win results. At the same time, the country should also introduce some policies to encourage downstream manufacturers to use domestic materials.

Inadequate protection of intellectual property rights hindered R&D initiative

Due to the insufficient protection of intellectual property rights by domestic laws, products and technologies developed over a long period of time are often counterfeited, stolen, and even the entire technical team is dug away, causing huge losses to the company. Due to the lack of respect for Chinese intellectual property rights, input and output are not proportional, which severely restricts the company's motivation for the development of key materials and components.

Therefore, many companies are willing to focus on short-term, fast, low-end manufacturing or downstream assembly with relatively low risks, and are unwilling to invest in high-tech industries with long technology research and development and high risks. Some companies, even if they want to develop high-tech products, have to adopt some security measures because they are worried about technology leaks.

Originally, high-tech development needs to share information and stimulate everyone’s inspiration to promote new ideas and solve problems encountered. However, due to confidentiality reasons, a lot of information cannot be shared and communicated on the technical team, which seriously affects the progress of the project and limits The rapid progress of technology research and development and successful trials. Therefore, strengthening the protection of intellectual property rights and escorting independent R&D companies with laws can enable Chinese companies that really invest in R&D and innovation to be rewarded, and companies that rely on speculation or plagiarism can be punished, and create a healthy development for companies to grow into hidden champions. surroundings.

Limitations of tax policies have hindered the development of key material R&D companies

The preparation of key materials and core components has the characteristics of high technical barriers and high added value, but it also has the risk of large R&D investment and long cycle. The activation labor cost of this kind of enterprise is mainly in terms of R&D investment, personnel wages, production area rent, etc., which is much higher than that of traditional enterprises. If the current value-added tax deduction method in China is used, this part of the cost cannot be deducted, which will make the tax burden of the enterprise. Higher, greatly reducing the profitability of the company, making the company do not have enough funds to invest in more research and development of new products and technologies in the early stage.

In fact, the Chinese government is also aware that value-added tax will affect the development of high-tech enterprises, so there are special value-added tax policies in some special fields such as software, chip and biopharmaceutical industries. However, key material manufacturing companies that are similar to these industries are currently unable to enjoy these special policies.

Therefore, if the state wants to solve the problem of key materials and core components, it must improve the inclusive tax policy that supports enterprise innovation, expand the scope of tax-preferential industries for high-tech enterprises, and effectively solve the tax dilemma faced by advanced material manufacturing enterprises, and reduce the burden on enterprises. Only by adding wings to innovation can it benefit the development of China's high-tech industry, and enable scientific and technological research-oriented companies that are willing to compete with foreign monopolies to truly embark on the path of becoming an invisible champion.

Cultivating invisible champion companies is a "breaking move" in China's industrial transformation and upgrading

For China to truly complete its economic transformation and transform from an economic power to a powerful country, it must put the key materials and components for solving the industry in the first place, and it must cultivate more invisible champions in order to truly achieve a large and strong industrial development, and to have independence. Right to speak. "Invisible champions" refer to those small and medium-sized enterprises that are very dedicated and have global or regional market leaders. Their products may be small, they do not meet directly with consumers, and they are not easily noticed. In addition, they are low-key and have relatively public visibility. Low, but they are often the game rules makers in their respective industries and the unshakable hegemon of industrial development.

Based on this, if Chinese companies want to become invisible champions, they need to have strong innovation capabilities, persist in long-term and unremitting research and development, and use ingenuity, patience, perseverance and confidence to achieve the ultimate in technology and materials.

Insist on innovation to occupy the commanding heights of technology

Whether a company can become an invisible champion in global competition depends on whether the company has strong innovation capabilities and whether it occupies the commanding heights of the world's key material preparation technology. Whether it is chips in the electronics industry, aircraft engines, or simple ballpoint pen cores and high-speed rail screws, they are all made with advanced technology and exquisite craftsmanship. To achieve the commanding heights of a field of technology, it is often not quickly obtained by a large number of people or short-term money. China’s past model of rapidly expanding its industry by relying on a large number of labor resources and a large amount of investment does not work.

At present, what China needs most is to form an innovative scientific research environment that can attract a group of world's top scientists to rest assured, occupy the commanding heights of technology through long-term innovation and technological accumulation, so as to solve the localization of key materials and components.

Insist on focus and perseverance to persevere unwavering

China has developed into the second largest economy in the world and has abundant labor resources, capital, talents, markets, and industrial chains. The biggest shortcoming is lack of patience and perseverance.

The development of modern industries is becoming more sophisticated, automated, and high-performance. These development trends place higher and higher requirements on key materials. At the same time, because key materials and components have a great impact on the performance of downstream products, there is often a winner-takes-all situation in the material field, that is, the best-doing company gradually becomes the invisible champion of the industry, forming a monopolistic situation of dominance and quality. Poor companies are basically unable to survive. China already has strong assembly capabilities. As long as it has key materials and components, it will quickly produce related products. Similarly, whoever monopolizes these key materials has the supreme right to speak in the industry chain.

The invisible champion enterprise is to stick to a sense of mission and national sentiment, not forget the original aspiration, and persevere until it succeeds once it recognizes a goal. This kind of dedication and long-term persistence is especially commendable in today's impetuous society.

Insist on the craftsman spirit to achieve the ultimate in products and craftsmanship

"Technology can be advanced, art can be linked to God." The core content of the craftsman spirit is to strive for perfection. To achieve the ultimate in products and work, we must rely on meticulous and rigorous and pragmatic attitudes. Continuous improvement, innovation and optimization of products must be It is the unswerving pursuit to master the top technology in the industry and create the highest quality products. I have visited a small and medium-sized enterprise that produces industrial fans in Germany. In order to detect the noise when the fans are running, I have specially built an advanced silent laboratory where I can hear my heartbeat.

In order to improve the quality, we are willing to invest and dare to invest. Such products will undoubtedly have strong international competitiveness. Craftsmanship is not only excellence, but also a pursuit, a responsible attitude, and a promise to endure loneliness. I think this should also become the pursuit of China's hidden champion companies, using the best technology to make the best products.

Source: Innovation Society

Scan the QR code to read on your phone

Online consultation

More information

Features of electromagnetic flowmeter

Introduction of electromagnetic flowmeter

Our company's patented products

Contact Us

Manager Zou:+86-18660362576

TEL:0086-631-5587383

FAX:0086-631-5305186

E-mail:18660362576@163.com

Quick Navigation

Online Message

Copyright Weihai Weiliu Measure & Control Instrument Co., Ltd 鲁ICP备15020907号-1 Powered by www.300.cn